Aerogels and Advanced Insulation: The Ultimate Guide for Energy-Efficient Buildings

Our buildings are silent energy consumers. They leak heat in the winter and absorb it in the summer. This constant energy exchange forces our HVAC systems to work overtime. The result is high utility bills and a significant environmental footprint. For decades, we have relied on bulky insulation materials to fight this battle. But what if we could do better? The future of construction lies in aerogel insulation for buildings and other advanced materials. These technologies offer a quantum leap in thermal performance. They promise a future of ultra-efficient buildings that are more comfortable, sustainable, and spacious.

This guide will take you on a deep dive into the world of superinsulation. We will explore the science behind aerogel, a material often called “frozen smoke.” You will learn how it and other advanced insulation materials are solving the biggest challenges in building design. From its incredible R-value to its space-saving profile, this technology is no longer confined to NASA labs. It is here, and it is ready to transform how we build and live.

The Energy Drain: Why Conventional Insulation Falls Short

Before we explore the future, we must understand the limitations of the present. Traditional insulation materials like fiberglass, cellulose, and rigid foam have been the industry standard for years. They have served us well. However, in the push towards net-zero energy buildings, their weaknesses become increasingly apparent.

The R-Value vs. Thickness Dilemma

The effectiveness of insulation is measured by its R-value. A higher R-value means better resistance to heat flow. The problem with conventional materials is that achieving a high R-value requires significant thickness.

- Fiberglass Batts: A common choice, but you need nearly 12 inches of it to achieve an R-value of R-38, a standard for modern attics.

- Rigid Foam Panels: Offer better performance per inch, but still require several inches of thickness for high-performance walls.

This need for thickness creates a major design constraint. It leads to thicker walls, which can reduce valuable interior floor space, especially in dense urban environments where every square foot counts.

Vulnerability to Environmental Factors

The performance of traditional insulation can degrade over time due to environmental factors.

- Moisture: Many conventional insulators, like fiberglass, lose a significant portion of their R-value when they get wet. Moisture can lead to mold, rot, and a decline in indoor air quality.

- Air Gaps: Improper installation can leave gaps and cracks. This allows for air leakage, creating thermal bridges that undermine the insulation’s effectiveness.

- Settling: Loose-fill insulation like cellulose can settle over time. This creates uninsulated voids at the top of wall cavities, reducing overall performance.

These limitations highlight the urgent need for a new class of materials. We need insulators that provide more R-value in less space and are resilient to the challenges of the real world.

What is Aerogel? The “Frozen Smoke” Revolutionizing Insulation

Aerogel seems like something from another world. It is a translucent, feather-light solid that has an ethereal, smoke-like appearance. Despite its delicate look, it is a powerful and robust material with a list of record-breaking properties. It is this unique combination that makes it the holy grail of insulation materials.

A Glimpse into its Structure

The secret to aerogel’s power lies in its internal structure. It is a synthetic porous material derived from a gel. In this gel, the liquid component has been replaced with a gas without significant collapse of the gel’s structure. The result is a solid that is over 99% air.

Imagine a sponge, but with pores that are a thousand times smaller than the width of a human hair. This nanoporous structure is what gives aerogel its extraordinary properties. Air is a poor conductor of heat, but it can transfer heat through convection (air movement). In aerogel, the air is trapped in these incredibly tiny pockets. The air molecules have no room to move, effectively stopping heat transfer by convection.

The Manufacturing Process: From Gel to Super-Insulator

Creating aerogel is a sophisticated scientific process. It generally involves two key stages:

- Sol-Gel Process: Chemical precursors, most commonly silica-based, are mixed in a solution. This creates a “sol,” which is a colloidal suspension of solid particles in a liquid. Over time, these particles link together to form a continuous, solid network throughout the liquid, creating a “gel.”

- Supercritical Drying: This is the critical step that gives aerogel its unique properties. The liquid inside the gel must be removed without causing the solid structure to shrink or collapse. To do this, scientists use a process called supercritical drying. The gel is placed in a pressure vessel, where the temperature and pressure are raised above the liquid’s “critical point.” At this point, there is no distinction between liquid and gas. The supercritical fluid can then be vented off as a gas, leaving the delicate, solid nanoporous structure perfectly intact.

The result is a material with incredibly low density and the lowest thermal conductivity of any known solid.

Unmatched Properties of Aerogel

- Extreme Low Thermal Conductivity: Aerogel is the most effective thermal insulator known. Its ability to trap air in nanosized pores virtually eliminates heat transfer.

- Incredibly Lightweight: Since it is mostly air, aerogel is exceptionally light. This makes it easy to transport and reduces the structural load on buildings.

- Hydrophobic Nature: Most commercial aerogels are treated to be hydrophobic, meaning they repel water. This prevents moisture from compromising their insulating performance.

- High Compressive Strength: Despite its low density, aerogel can support significant weight.

- Excellent Acoustic Insulation: The same structure that traps heat also traps sound waves, making it an effective acoustic insulator.

- Fire Retardant: Silica-based aerogels are non-combustible and can withstand extremely high temperatures, adding a layer of fire safety to buildings.

The Power of Aerogel Insulation for Buildings

When these incredible properties are applied to the construction industry, they solve some of the most persistent challenges in creating energy-efficient buildings. The use of aerogel insulation for buildings is not just an incremental improvement; it is a fundamental shift in what is possible.

Unprecedented Thermal Performance (High R-Value)

The headline benefit of aerogel is its phenomenal R-value per inch.

- Aerogel: Can achieve R-values of R-10 or more per inch.

- Polyisocyanurate Foam: Around R-6.5 per inch.

- Fiberglass Batts: Around R-3.5 per inch.

This means a 1-inch thick aerogel blanket can provide the same insulating power as a 3-inch thick fiberglass batt. This performance advantage is a game-changer for building design.

| Insulation Material | Typical R-Value per Inch |

| Aerogel Blanket | R-10.3 |

| Closed-Cell Spray Foam | R-7.0 |

| Polyisocyanurate (Polyiso) | R-6.5 |

| Extruded Polystyrene (XPS) | R-5.0 |

| Fiberglass Batt | R-3.5 |

Thin Profile, Maximum Space

Because aerogel is so efficient, you need much less of it. This thin profile has massive implications for architecture and construction.

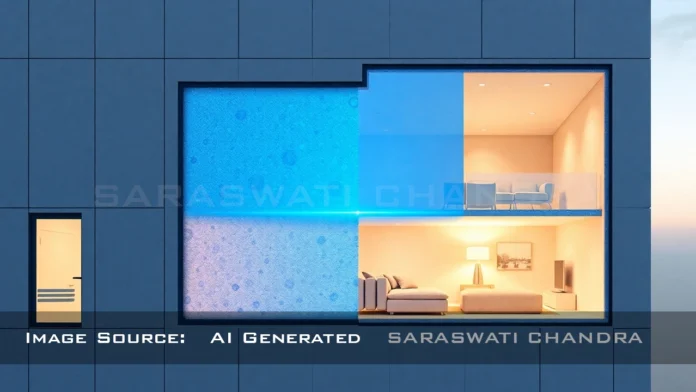

- Thinner Walls, More Floor Space: In new construction, using aerogel can reduce wall thickness by several inches. In a large building, this can add up to thousands of square feet of usable (and sellable) interior space.

- Easier Retrofitting: Retrofitting old buildings, especially historic ones with solid masonry walls, is a major challenge. It is often impossible to add thick insulation to the interior without ruining architectural details. Thin aerogel blankets can be applied directly to the interior surface, providing a significant thermal upgrade with minimal disruption.

Moisture and Fire Resistance

Aerogel’s inherent durability provides peace of mind and long-term performance.

- Hydrophobic Properties: Aerogel blankets repel water. This means they will not lose their R-value if exposed to moisture, and they do not support the growth of mold or mildew. This makes them ideal for basements, bathrooms, and other damp environments.

- Fire Safety: Silica aerogel is non-combustible. It does not burn or release toxic smoke, which can significantly improve the fire safety rating of a wall or roof assembly.

Versatile Applications in Architecture

Aerogel is not a single product but a technology that comes in various forms, making it incredibly versatile.

- Aerogel Blankets: The most common form for construction. Flexible blankets made of silica aerogel embedded in a fibrous batting. They are easy to cut and install around pipes, wires, and complex framing.

- Boards and Panels: Rigid aerogel boards offer a high-performance solution for continuous exterior insulation, roofing, and flooring.

- Translucent Aerogel (Daylighting): Some forms of aerogel are translucent. They can be placed between panes of glass to create highly insulating windows and skylights that still allow for diffuse, natural light.

- Coatings and Plasters: Aerogel can be ground into a powder and mixed with plaster or paint. This creates a thin, insulating coating that can be applied to walls to improve thermal performance and prevent condensation.

Beyond Aerogel: Other Advanced Insulation Materials

Aerogel is a star player, but it is not the only high-performance option. A new generation of superinsulation materials is emerging, each with unique strengths.

Vacuum Insulated Panels (VIPs)

Vacuum Insulated Panels are the other heavyweight champion of thermal performance. A VIP consists of a rigid, porous core material that is evacuated of air and sealed in a thin, gas-tight envelope.

- How They Work: By removing virtually all the air, a vacuum eliminates heat transfer by convection and conduction. This gives VIPs an incredible R-value, often ranging from R-30 to R-50 per inch.

- Pros: The highest R-value per inch of any commercially available insulation. Excellent for applications where space is extremely limited, like insulating refrigerators or high-end building facades.

- Cons: The primary drawback is fragility. If the vacuum envelope is punctured, the panel loses its insulating properties completely. This requires extremely careful handling and installation. They also cannot be cut or modified on site.

Gas-Filled Panels (GFPs)

Gas-filled panels are similar in concept to double-paned windows. They consist of a multi-chambered plastic honeycomb structure filled with a low-conductivity, inert gas like argon or krypton. They offer a good balance of performance and practicality.

- Performance: GFPs offer a better R-value than foam (around R-15 per inch) but are not as powerful as VIPs or aerogel.

- Advantages: They are more robust than VIPs and are not susceptible to total failure from a small puncture.

Phase-Change Materials (PCMs)

Phase-change materials represent a “smart” approach to insulation. They do not just resist heat flow; they actively manage it.

- How They Work: PCMs are materials that absorb and release large amounts of thermal energy (latent heat) when they change phase (e.g., from solid to liquid). They are typically microencapsulated and mixed into other building materials like drywall or insulation.

- Application: When the room temperature rises, the PCM melts, absorbing heat and keeping the room cool. When the temperature drops, the PCM solidifies, releasing the stored heat and warming the room. This helps to stabilize indoor temperatures and reduce peak loads on HVAC systems.

A Practical Guide: Implementing Advanced Insulation in Your Project

Adopting these next-generation materials requires a shift in thinking and planning. It’s about targeting the right applications to maximize value.

New Construction vs. Retrofitting

- New Construction: This is the ideal scenario to leverage aerogel insulation for buildings. It can be designed into the building envelope from the start. This allows architects to create thinner wall assemblies, maximize interior space, and eliminate thermal bridges more effectively.

- Retrofitting: This is where aerogel’s thin profile truly shines. It is often the only viable solution for upgrading the thermal performance of historic or space-constrained buildings. Thin aerogel blankets can be applied to the interior of solid brick walls or to the inside of roof assemblies without significantly altering the building’s character or dimensions.

Identifying Critical Areas for Superinsulation

You don’t necessarily need to wrap an entire building in aerogel. A strategic approach often yields the best return on investment. Focus on areas where heat loss is most concentrated:

- Thermal Bridges: These are parts of the building envelope where heat flows more easily, such as steel studs, concrete slab edges, and window frames. Applying strips of aerogel over these elements can dramatically improve the overall performance of the wall.

- Window and Door Frames: The junction between a window and the wall is a classic weak point. Insulating this area with aerogel can significantly reduce drafts and heat loss.

- Roofs and Attics: Given that heat rises, roofs are a major source of energy loss. High-performance, thin insulation can be particularly useful in cathedral ceilings where there is limited space for traditional insulation.

Cost-Benefit Analysis: Is the Investment Worth It?

The biggest question surrounding advanced insulation is cost. There is no denying that materials like aerogel and VIPs have a much higher upfront cost than fiberglass.

However, a simple cost comparison is short-sighted. A proper analysis must consider the long-term value:

- Energy Savings: The dramatic reduction in heating and cooling costs provides a direct return on investment over the life of the building.

- Increased Property Value: In new construction, the extra usable floor space gained by using thinner walls has a direct and often immediate monetary value.

- Enhanced Comfort and Health: A super-insulated home has more stable temperatures, fewer drafts, and is less prone to mold, leading to a higher quality of life.

- Future-Proofing: Building codes are continuously demanding higher levels of energy efficiency. Using advanced insulation today ensures a building will meet or exceed standards for decades to come.

Frequently Asked Questions (FAQ)

How much does aerogel insulation cost?

Aerogel insulation is a premium product. It can cost $5 to $10 per square foot for a blanket with an R-value of around R-10. While this is significantly more than traditional insulation, prices are steadily decreasing as manufacturing scales up.

Is aerogel insulation better than foam?

In terms of thermal performance per inch, yes, aerogel is significantly better than any foam insulation. A one-inch aerogel blanket can have a higher R-value than two inches of closed-cell spray foam. It is also more fire-resistant and hydrophobic.

Can you use aerogel in residential homes?

Absolutely. While it started in industrial and aerospace applications, aerogel is increasingly being used in high-performance residential construction and retrofitting. It is especially popular for projects aiming for Passive House or Net-Zero Energy standards.

What is the R-value of aerogel?

The R-value of aerogel is typically around R-10.3 per inch of thickness. This is approximately three times higher than the R-value of traditional fiberglass or cellulose insulation.

Is aerogel insulation safe?

Yes. Silica aerogel, the type used in construction, is safe to handle. It is essentially a form of amorphous silica, similar to sand. The aerogel is embedded in a durable fiber matrix, and installers should wear standard personal protective equipment (gloves, glasses, mask) to avoid irritation from dust when cutting the material.

Conclusion: The Future of Building Envelopes is Super-Insulated

The quest for truly energy-efficient buildings has led us to a new frontier in material science. Aerogel insulation for buildings, along with VIPs and other advanced materials, offers a pathway to a more sustainable future. These technologies allow us to break free from the old constraints of thickness and R-value. They enable us to design buildings that are not only high-performance but also more spacious, resilient, and comfortable.

The upfront cost remains a hurdle, but the trajectory is clear. As production increases and costs fall, superinsulation will move from a niche product to a new standard. It is an investment in long-term energy savings, occupant well-being, and the health of our planet. The era of the passive, energy-leaking building is over. The future is thin, smart, and super-insulated.

What are your thoughts on using advanced insulation? Have you considered it for a project? Share your questions and experiences in the comments below!