One Day, One Challenge: A Case Study on Transforming a Site with AI in Bihar Construction

The landscape of Bihar is changing. Infrastructure projects are booming. Yet, many face timeless challenges. Remote locations create logistical nightmares. Delays are common. Quality control is difficult. We embarked on a one-day challenge to tackle these issues head-on. This is the story of how we used advanced technology to transform a remote construction site. It demonstrates the profound potential of AI in Bihar construction. Our goal was simple. We wanted to prove that a single day of intervention with drones and artificial intelligence could deliver more insight than weeks of traditional methods.

Construction in remote areas often feels like a battle against the odds. This project was no different. It was situated miles from the nearest city. The terrain was difficult. Access was limited. The project managers in their city office relied on daily reports. These reports were often subjective and delayed. They lacked the granular data needed for precise decision-making. This disconnect between the site and the office was the root cause of many problems. It led to budget overruns and timeline extensions. We knew technology held the key to bridging this gap.

The Old Way: Traditional Hurdles on a Remote Bihar Site

Before deploying our solution, we took stock of the existing problems. Understanding these pain points is crucial. It highlights the true value of technological intervention. The site operated on a model that has been used for decades. While effective in its own right, it was not efficient.

Logistical Nightmares and Delays

Every day began with uncertainty. Was the shipment of steel arriving? Did the cement mixer have enough fuel? These simple questions were hard to answer. Communication was patchy. The site supervisor spent hours on the phone. He coordinated supplies instead of managing work on the ground. This constant firefighting meant progress was slow and unpredictable.

A Glaring Lack of Real-Time Data

Project managers relied on photographs and written reports. These were sent at the end of each day. By the time they reviewed the information, it was already 24 hours old. A problem that occurred in the morning could go unnoticed until the next day. This lag time was costly. It prevented proactive problem-solving. Decisions were always reactive.

Pervasive Safety and Security Concerns

Construction sites are inherently dangerous. On a remote site, these risks are magnified. Monitoring every corner of a large area is impossible for a small team. Unsafe practices could go unseen. Additionally, theft of materials was a constant worry. Securing the perimeter and valuable assets overnight was a major challenge.

Inconsistent Quality Control

Ensuring every aspect of the construction meets quality standards is vital. With manual methods, this is a spot-check process. A supervisor can only be in one place at a time. It is easy to miss small deviations from the blueprints. Over time, these small errors can compound into significant structural issues. The lack of a comprehensive overview made quality assurance a game of chance.

The New Way: A One-Day Tech-Infusion

Our challenge was set. We had one day to deploy our drone and AI platform. We aimed to provide the project team with a level of clarity they had never experienced before. The day was structured into three distinct phases.

Phase 1: Morning (08:00 AM) – The Aerial Survey

The day began with the drone. Our licensed pilot launched a state-of-the-art quadcopter equipped with a high-resolution RGB camera.

- Flight Plan: We created an automated flight path. The drone would cover the entire 15-acre site systematically. This ensures complete coverage with no blind spots.

- Data Capture: The drone flew at a precise altitude. It captured thousands of overlapping high-resolution images. This process, known as photogrammetry, took just 45 minutes.

- Safety Check: During its flight, the drone also performed a visual sweep for immediate safety hazards. It identified workers without helmets and improperly stored materials.

This initial flight provided a complete, high-fidelity snapshot of the site as it stood at the start of the day.

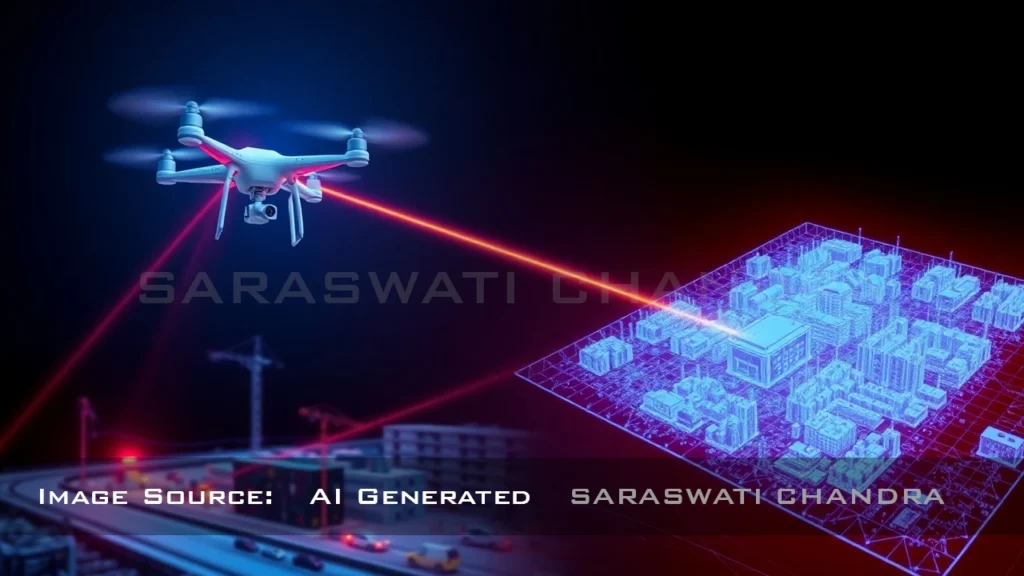

Phase 2: Mid-day (12:00 PM) – AI-Powered Data Processing

The images from the drone were just raw data. The magic happens when AI gets to work. We uploaded the thousands of images to our cloud-based AI platform.

The platform began its work instantly.

- Creating a 3D Model: The AI stitched the images together. It created a photorealistic, geographically accurate 3D model of the entire site. This “digital twin” was the foundation for all further analysis.

- Analyzing Progress: The AI compared the 3D model against the project’s digital blueprints (BIM/CAD models). It automatically identified what work had been completed. It also flagged any deviations from the original plan.

- Calculating Volumes: A major task on any construction site is managing earthwork. The AI calculated the exact volume of soil excavated. It also measured the stockpiles of materials like sand and gravel. This eliminated guesswork entirely.

By lunchtime, the project manager had a complete digital replica of their site on their laptop. They could explore it from any angle. They could measure distances, areas, and volumes with centimeter-level accuracy.

Phase 3: Afternoon (04:00 PM) – Actionable Insights and Decisions

The final phase was about turning data into decisions. The AI platform generated a comprehensive report. This was not a simple document. It was an interactive dashboard.

- Progress Report: It showed that 70% of the foundation work was complete. This was 5% ahead of schedule. This was motivating news for the team.

- Deviation Alert: The AI flagged a retaining wall being built 10 centimeters off its planned location. This was a minor error. But, if left uncorrected, it could have caused major problems later. The site supervisor was alerted immediately and corrected the issue.

- Inventory Check: The stockpile measurements showed they had enough gravel for two more days. However, the sand stockpile was running low. The project manager placed a new order immediately. This prevented a potential work stoppage.

- Safety Briefing: The report included images of the safety violations observed in the morning flight. This was used for a targeted toolbox talk with the crew, reinforcing safety protocols without blame.

In just one day, the team moved from reactive problem-solving to proactive project management.

The Transformative Impact of AI in Bihar Construction

The one-day challenge was a resounding success. It provided a clear, measurable demonstration of the benefits. The impact of implementing AI in Bihar construction was felt across four key areas, showcasing a new frontier for the industry.

Unprecedented Speed and Accuracy

What once took days of manual surveying and estimation was accomplished in hours. The accuracy of the AI’s calculations was far superior to traditional methods.

- Time Saved: A manual topographic survey would have taken a week. The drone did it in under an hour.

- Error Reduction: Manual measurements are prone to human error. The AI’s analysis is objective and consistent. This reduces the risk of costly rework.

Enhancing Worker Safety and Site Security

Technology acted as a tireless safety officer. The ability to monitor the entire site from above is a game-changer for safety management.

- Hazard Identification: The drone can spot potential risks that a supervisor on the ground might miss. This includes things like unstable slopes or unsafe scaffolding.

- Incident Response: In case of an emergency, a drone can provide a quick aerial view to first responders. This helps them assess the situation before entering a potentially hazardous area.

- Security Monitoring: Regular drone flights can deter theft. They create a record of site activity, making it easier to identify unauthorized access.

Massive Cost Savings and Resource Optimization

Efficiency directly translates to cost savings. By providing accurate data, AI and drones help optimize the use of every resource.

- Material Management: Precise stockpile measurements prevent over-ordering or running out of critical materials. This minimizes waste and avoids costly delays.

- Equipment Utilization: By tracking progress, managers can better schedule heavy equipment. This ensures expensive machinery is not sitting idle.

- Reduced Rework: Catching errors early, like the misplaced retaining wall, saves enormous amounts of money. Rework is one of the biggest hidden costs in construction.

Bridging the Communication Gap

The AI platform created a single source of truth. Everyone, from the project owner to the site engineer, was looking at the same data.

- Clearer Reporting: Interactive 3D models are much easier to understand than complex spreadsheets and drawings. This improves communication among all stakeholders.

- Remote Management: The project manager in the city could “walk the site” virtually. They could make informed decisions without needing to be physically present every day. This is a huge advantage for remote construction site monitoring.

A Deeper Dive: How the Technology Works

To appreciate the revolution, it helps to understand the components. The system is a synergy of hardware and software. It is a perfect example of modern drone technology in construction.

The Role of Drones: The Eyes in the Sky

The drone is more than a flying camera. It is a sophisticated data collection tool. Different projects may require different types of sensors.

- Photogrammetry (RGB Cameras): This is the most common method. It uses high-resolution photos to create 3D models and orthomosaic maps (a single, high-resolution map of the entire site).

- LiDAR (Light Detection and Ranging): LiDAR sensors use laser pulses to create incredibly dense and accurate 3D point clouds. This is ideal for projects requiring extreme precision or for surveying areas with vegetation.

- Thermal Imaging: Thermal cameras can detect heat signatures. In construction, this can be used to find water leaks in roofing, identify faulty electrical components, or check the curing of concrete.

The AI Brain: From Pixels to Progress Reports

The artificial intelligence platform is where the raw data becomes intelligent insight. It uses a combination of computer vision and machine learning algorithms.

- Object Recognition: The AI is trained to recognize various objects on a construction site. It can identify equipment, materials, and even workers.

- Change Detection: By comparing scans from different days, the AI automatically tracks progress. It highlights what has changed, what has been added, and what has been removed.

- Predictive Analytics: Advanced AI models can even use current progress data to predict future outcomes. They can forecast project completion dates and potential budget overruns.

The Integrated Platform: A Single Source of Truth

All this information is useless if it is not accessible. The data is presented in a cloud-based platform that anyone with permission can access.

- Web-Based Dashboard: No special software is needed. Stakeholders can log in from any web browser on their laptop or tablet.

- Collaboration Tools: Team members can make annotations directly on the 3D model. They can tag colleagues and assign tasks related to specific issues found on the site.

- Historical Data: The platform stores all past surveys. This creates an invaluable as-built record of the entire construction process. It is useful for maintenance and future renovations.

Beyond the One-Day Challenge: The Future of Construction in India

This case study is not just about one project in Bihar. It is a blueprint for the future. The challenges faced on this remote site are common across India. The successful application here proves the scalability and adaptability of this technology. This is the new age of construction technology India.

Scalability Across Other Remote Regions

From the mountains of Himachal Pradesh to the plains of Uttar Pradesh, infrastructure projects face similar hurdles. This tech-stack can be deployed anywhere. It democratizes access to high-quality project management tools. It levels the playing field for projects far from urban centers.

The Role of Government and Policy

The Indian government’s focus on infrastructure development is a massive opportunity. Policies that encourage or even mandate the use of technology for large public projects could accelerate adoption. Incentives for companies that invest in digital construction tools would boost efficiency and transparency across the board.

Training the Next Generation of Construction Professionals

The construction worker of the future will be more tech-savvy. Civil engineers will need skills in data analysis. Site supervisors will need to be comfortable using digital platforms. Educational institutions and vocational training centers must adapt their curriculum. They need to prepare students for a digitally-driven construction industry. This is essential for long-term growth.

Frequently Asked Questions (FAQ)

We often get questions about the practical aspects of using this technology. Here are some of the most common ones.

Is this technology too expensive for smaller construction companies?

This is a common misconception. Initially, the investment might seem high. However, the cost of drone hardware and AI software has dropped significantly. More importantly, the return on investment (ROI) is very fast. The money saved by preventing just one major rework incident can often pay for the entire system. Many companies also offer this as a service, removing the need for a large upfront capital expense.

How does bad weather like rain or strong winds affect drone operations?

Weather is a valid concern. Drones cannot fly in heavy rain or very high winds. However, professional-grade drones are more robust than consumer models. They can handle moderate wind and light drizzle. Flight planning takes weather forecasts into account. Since a full survey takes less than an hour, it’s usually easy to find a suitable window for operation, even during monsoon season.

What kind of skills are needed to operate these systems?

Operating the drone requires a licensed and trained pilot. This is a specialized skill. However, using the AI platform is designed to be intuitive. Project managers and engineers do not need to be data scientists. The interface is user-friendly, with dashboards and reports that are easy to understand. Basic training is usually provided by the technology vendor.

Can AI and drones completely replace human supervisors on a construction site?

No, and that is not the goal. This technology is a tool to augment human capabilities, not replace them. It empowers site supervisors and project managers. It frees them from tedious manual tasks like measuring and reporting. This allows them to focus on what they do best: managing people, solving complex problems, and ensuring quality craftsmanship.

How secure is the project data collected by the drones and stored on the cloud?

Data security is a top priority. Reputable AI platform providers use robust security measures. This includes data encryption both in transit and at rest. They use secure cloud infrastructure like AWS or Azure. Access controls ensure that only authorized personnel can view or edit the project data.

Conclusion: The Dawn of a New Construction Era

Our one-day challenge on a remote site in Bihar did more than just gather data. It painted a vivid picture of the future. A future where every construction project, no matter how remote, can benefit from precision, safety, and efficiency. The integration of AI in Bihar construction is not a distant dream; it is a present-day reality with proven results.

This technology transforms projects from a series of isolated tasks into a connected, data-driven ecosystem. It breaks down silos between the office and the field. It replaces guesswork with certainty. As India continues its journey of rapid development, embracing such innovations will be the key to building faster, smarter, and safer. The transformation has begun.

What are your thoughts on the role of technology in construction? Have you seen similar innovations on projects you know? Share your insights in the comments below! If you found this case study valuable, please share it with your network.