Pavement Design: The Ultimate Guide for Building Roads That Last

Roads are the arteries of our economy and society. They connect cities, enable trade, and facilitate our daily lives. At the heart of every durable road is a discipline that blends science and engineering: Pavement Design. This critical process involves the structural design of a road’s surface to withstand traffic loads and environmental conditions. A well-designed pavement provides a safe, smooth, and long-lasting surface for travel.

This comprehensive guide will navigate the intricate world of Pavement Design. We will explore the fundamental differences between flexible and rigid pavements. We will also dive deep into the specific design methodologies, including the influential IRC guidelines. Whether you are an engineering student or a practicing professional, this article will serve as your definitive resource for creating resilient and cost-effective road networks.

What is Pavement Design and Why is it Essential?

Pavement design is the process of creating a layered structure that can effectively support traffic loads. The primary goal is to transfer the concentrated loads from vehicle wheels to the natural soil (subgrade) without causing damage. The pavement must spread the load over a wide area. This reduces the stress on the subgrade to a level it can safely handle.

The core objectives of a good pavement design are:

- Structural Adequacy: The pavement must be strong enough to resist the anticipated traffic loads for its entire design life without structural failure.

- Functional Performance: It must provide a smooth and comfortable riding surface with adequate skid resistance for safety.

- Economic Viability: The design should be the most economical option, considering both initial construction costs and long-term maintenance costs.

- Durability: It must withstand the damaging effects of weather, such as temperature variations and moisture.

Neglecting proper pavement design leads to premature failures like cracking, rutting, and potholes. This results in costly repairs, traffic disruptions, and compromised safety.

The Two Major Types of Pavements: A Head-to-Head Comparison

Pavements are broadly classified into two main categories based on how they distribute loads. Understanding this difference is fundamental to the entire design process.

Flexible Pavements: The Asphalt Advantage

A flexible pavement consists of multiple layers of materials, with the highest quality materials at the top. The most common type uses asphalt concrete (bitumen) as the surface course.

- Load Distribution: Flexible pavements transfer wheel loads to the subgrade through a grain-to-grain mechanism. The load is spread in a cone-like shape, decreasing in intensity as it moves down through the layers.

- Structure: It is a multi-layered system, typically including a wearing course, binder course, base course, and sub-base course over the compacted subgrade.

- Characteristics: They have lower flexural strength and are more “flexible” under load. Any deformation in the subgrade is reflected in the upper layers.

Rigid Pavements: The Concrete Standard

A rigid pavement uses Portland Cement Concrete (PCC) for its surface course. It may or may not have a base course beneath it.

- Load Distribution: Rigid pavements have very high flexural strength (or beam strength). The concrete slab acts like a beam, distributing the wheel load over a very wide area of the subgrade.

- Structure: The primary structural component is the concrete slab itself. This slab possesses significant rigidity.

- Characteristics: Due to their rigidity, they are less sensitive to minor subgrade imperfections. Temperature and moisture changes can induce significant stresses in the slab, requiring carefully designed joints.

A Deep Dive into Flexible Pavement Design

Flexible pavements are the most common type of road surface in the world. Their design is a complex process that balances material properties with traffic demands.

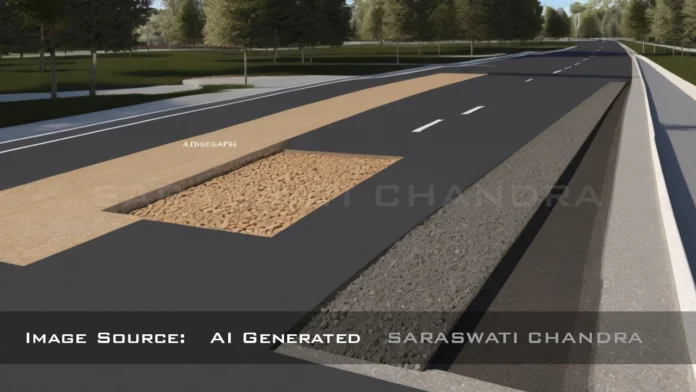

Understanding the Layered Structure

Each layer in a flexible pavement has a specific function:

- Subgrade: This is the natural soil that the pavement is built upon. Its strength is the foundation of the entire design. We usually measure its strength using the California Bearing Ratio (CBR) test.

- Sub-base Course: This layer is placed directly over the subgrade. It provides structural support, improves drainage, and prevents fine subgrade particles from moving into the pavement structure.

- Base Course: This is a high-quality, load-bearing layer. It distributes the load from the surface and provides the main structural capacity of the pavement.

- Bituminous Layers (Binder and Wearing Course): These asphalt layers provide a smooth, waterproof, and skid-resistant surface. The wearing course is the top layer that directly contacts traffic.

Key Design Parameters for Flexible Pavements

The design process involves analyzing several key inputs:

- Traffic Analysis: We must estimate the total traffic the pavement will carry over its design life. This is expressed in terms of Million Standard Axles (MSA). We convert all different vehicle axle loads into an equivalent standard 80 kN axle load.

- Subgrade Strength: The CBR value of the subgrade soil is a critical input. A lower CBR value means a weaker soil, which will require a thicker pavement structure.

- Material Properties: The strength and stiffness (resilient modulus) of the materials used in each layer are essential for a mechanistic design approach.

- Environmental Factors: Temperature and rainfall can affect the performance of the asphalt and underlying layers.

Following IRC Guidelines for Flexible Pavement Design (IRC: 37)

The Indian Roads Congress (IRC) provides specific guidelines for Pavement Design. For flexible pavements, IRC: 37 is the governing document in India and is widely referenced elsewhere.

IRC: 37 primarily uses an empirical approach based on extensive performance data. The design process involves:

- Determining the design traffic in MSA for the chosen design life.

- Determining the effective CBR of the subgrade soil.

- Using design charts provided in the code to find the required total thickness of the pavement and the thickness of each individual layer.

These charts are based on decades of research and provide a reliable method for designing pavements for various traffic and soil conditions.

The Role of Fatigue and Rutting Criteria

Modern mechanistic-empirical design methods go beyond the simple charts. They analyze the pavement’s response to loads in terms of stress and strain. The two primary failure criteria are:

- Fatigue Cracking: This is caused by repeated bending of the asphalt layer under traffic loads. The design limits the horizontal tensile strain at the bottom of the asphalt layer to prevent premature cracking.

- Rutting (Permanent Deformation): This is the formation of wheel path depressions in the pavement. It is caused by the accumulation of small, permanent deformations in the subgrade and other layers. The design limits the vertical compressive strain on top of the subgrade to control rutting.

Advanced design software uses these criteria to create a more optimized and reliable pavement structure.

Mastering Rigid Pavement Design

Rigid pavements are known for their long life and low maintenance requirements, especially under heavy traffic. Their design philosophy is quite different from that of flexible pavements.

The Anatomy of a Concrete Pavement

A typical rigid pavement system includes:

- Subgrade: As with flexible pavements, this is the underlying natural soil. Its support is characterized by the Modulus of Subgrade Reaction (k-value).

- Base/Sub-base Course: A granular or stabilized layer is often placed under the concrete slab. It provides uniform support, prevents pumping (the ejection of water and fines), and acts as a construction platform.

- Concrete Slab: This is the main event. The Portland Cement Concrete (PCC) slab provides almost all of the pavement’s structural capacity. Its thickness is the primary output of the design process.

Critical Design Factors for Rigid Pavements

The design of a concrete slab is governed by the stresses induced within it.

- Wheel Load Stresses: The primary stress is the flexural (bending) stress caused by vehicle wheel loads. The design ensures this stress remains well below the concrete’s flexural strength (or modulus of rupture). Westergaard’s analysis provides the foundational theory for calculating these stresses.

- Temperature Stresses: This is a unique and critical factor for rigid pavements.

- Warping Stresses: Occur due to a temperature differential between the top and bottom of the slab (day vs. night).

- Frictional Stresses: Occur due to the overall expansion and contraction of the slab with seasonal temperature changes.

- Combined Stresses: The design must consider the combined effect of wheel load and temperature stresses. The most critical condition often occurs at the corners or edges of the slab.

Adhering to IRC Guidelines for Rigid Pavement Design (IRC: 58)

IRC: 58 is the code of practice for Pavement Design of rigid pavements in India. The design process involves:

- Determining the design traffic in terms of cumulative repetitions of different axle loads.

- Determining the properties of the concrete (flexural strength) and the subgrade (k-value).

- Calculating the stresses due to wheel loads using design charts based on Westergaard’s theory.

- Calculating the warping stresses due to temperature differentials.

- Combining these stresses and checking them against the concrete’s strength using a fatigue analysis approach. The design ensures the cumulative fatigue damage over the pavement’s life is less than 1.

Joint Design: The Key to Longevity

Because concrete expands and contracts significantly, joints are essential to control cracking.

- Contraction Joints: These are saw-cut joints that create weakened planes to control where random cracking occurs.

- Expansion Joints: These provide space for the slab to expand, preventing compressive stresses. They are used at intersections with structures like bridges.

- Construction Joints: These are placed at the end of a day’s paving.

- Dowel bars and tie bars are often used at joints to transfer loads and hold adjacent slabs together. Proper joint design is as important as the slab thickness itself.

The Future of Pavement Technology

The world of Pavement Design is continuously evolving. Researchers are developing new technologies to create more durable, sustainable, and intelligent roads.

- Perpetual Pavements: These are flexible pavements designed with a super-strong, rut-resistant base. They are designed to last for over 50 years with only periodic replacement of the top wearing course.

- Sustainable Materials: The use of recycled materials like reclaimed asphalt pavement (RAP), recycled concrete aggregate, and plastics in pavement construction is growing.

- Smart Pavements: This involves embedding sensors into the pavement to monitor traffic loads, temperature, moisture, and structural health in real-time. This data can optimize maintenance and improve traffic management.

Frequently Asked Questions (FAQ)

What are the two main types of pavement?

The two main types are flexible pavements and rigid pavements. Flexible pavements use asphalt as the surface and distribute loads in layers. Rigid pavements use a concrete slab that distributes loads over a wide area due to its high stiffness.

What is the main objective of pavement design?

The main objective of pavement design is to create a structurally sound and economical road structure. It must safely transfer traffic loads to the subgrade soil for a specified design life without showing premature distress like cracking or rutting.

What is the difference between flexible and rigid pavement design?

The key difference lies in the design philosophy. Flexible pavement design focuses on a layered system where the total thickness is determined to protect the subgrade. Rigid pavement design focuses on determining the thickness of the concrete slab to resist bending stresses from loads and temperature.

What is IRC 37 used for?

IRC: 37 is the Indian Roads Congress code of practice for the design of flexible pavements. It provides a set of guidelines and design charts to determine the required thickness of pavement layers based on traffic volume (MSA) and subgrade strength (CBR).

Conclusion: Building Roads That Last

Effective Pavement Design is a testament to meticulous engineering. It is the invisible science that underpins our mobility and economic vitality. By understanding the distinct behaviors of flexible and rigid pavements and by rigorously applying design principles and guidelines, we can create road networks that are safe, durable, and sustainable.

From analyzing traffic loads and soil strength to considering the fine details of fatigue criteria and joint spacing, every step is crucial. As technology advances, the tools at our disposal will become even more powerful, enabling us to build the resilient infrastructure that future generations will depend on.

What challenges have you faced in pavement design projects? Share your experiences or questions in the comments section below!