Chenab Bridge: How India Built the World’s Highest Railway Bridge

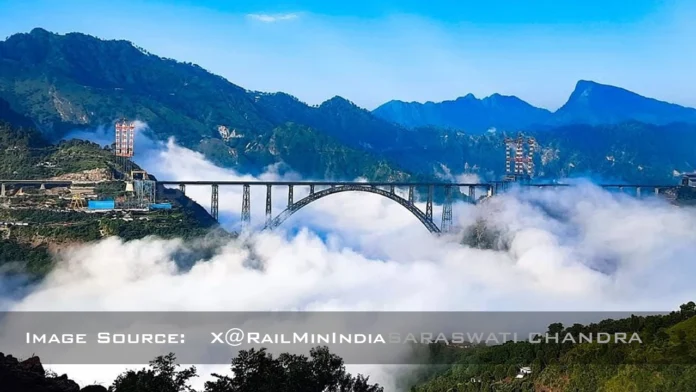

In the heart of the Himalayas, an engineering titan stands tall. It slices through the clouds, defying gravity and nature itself. This is the story of the Chenab Bridge, an icon of human ingenuity. It is a structure that does more than connect two points. It connects a nation’s ambition with its future. This article unveils how the Chenab Bridge became the world’s highest railway bridge. We will journey through its conception, challenges, and groundbreaking construction. This structure is a testament to India’s engineering prowess, standing 359 meters (1,178 feet) above the riverbed. It is a symbol of progress, etched against a backdrop of one of the world’s most formidable mountain ranges.

This colossal arch bridge is the centerpiece of a much larger vision. It represents a promise of all-weather connectivity to the Kashmir Valley. Moreover, it showcases a new era of infrastructure development in India. Join us as we explore the journey of this magnificent structure. From the drawing board to its triumphant completion, every step is a lesson in perseverance.

A Dream of Connectivity: The Genesis of the USBRL Project

The story of the Chenab Bridge is inseparable from its parent project. This project is the Udhampur-Srinagar-Baramulla Rail Link (USBRL). For decades, connecting the Kashmir Valley to the rest of India by rail was a monumental dream. The region’s harsh geography and extreme weather made this dream seem almost impossible. The existing road network, particularly the Jammu-Srinagar National Highway, is often closed in winter due to heavy snowfall and landslides. This isolation severely impacts the economy, security, and daily life of the people in the valley.

Therefore, the Government of India declared the USBRL project a “National Project” in 2002. This designation underscored its strategic importance. The goal was simple but audacious. It was to build a reliable, all-weather, and cost-effective railway line through the treacherous Himalayas.

The USBRL project is a 272-kilometer-long railway line. It is divided into four main sections. While some parts were relatively straightforward, the Katra to Banihal section was the ultimate challenge. This 111-kilometer stretch cuts through the most rugged terrain of the Pir Panjal range. This section alone features dozens of tunnels and bridges.

At the heart of this section lay the biggest obstacle of all. This was the deep, expansive gorge carved by the Chenab River. There was no way around it. The only solution was to go over it. This necessity gave birth to the concept of the Chenab Bridge, a structure that would need to be stronger, taller, and more resilient than any built before it in such a hostile environment. The world’s highest railway bridge was not just an ambition; it was a geographical necessity.

The Anatomy of a Giant: Chenab Bridge by the Numbers

To truly grasp the scale of the Chenab Bridge, one must look at its incredible statistics. These numbers paint a picture of a structure built to endure for generations. Each figure represents a conquered challenge and an engineering milestone.

- Height: 359 meters (1,178 feet) from the riverbed, making it the world’s highest railway bridge. To put this in perspective, it is 35 meters taller than the Eiffel Tower.

- Total Length: 1,315 meters (4,314 feet).

- Arch Span: The main steel arch spans a massive 467 meters (1,532 feet). This is the longest arch span for a broad-gauge railway in India.

- Steel Used: Approximately 28,660 metric tonnes of structural steel were used. The steel was specially developed to withstand temperatures as low as -20°C.

- Concrete Used: Over 66,000 cubic meters of concrete were used for the foundations and viaduct piers.

- Design Life: The bridge is designed to have a lifespan of 120 years.

- Train Speed: It is designed to allow trains to travel at speeds up to 100 kilometers per hour.

- Wind Resistance: The structure is designed to withstand wind speeds of up to 266 kilometers per hour.

These are not just numbers on a page. They represent a colossal effort in design, material science, and construction management. The bridge’s design ensures it remains operational and safe, even in the face of nature’s fury.

Conquering the Himalayas: Overcoming Unprecedented Challenges

Building the Chenab Bridge was a constant battle against nature and logistics. The engineers and workers faced a set of challenges that were unique and extreme. Overcoming them required innovation, courage, and meticulous planning.

The Geological Gauntlet

The Himalayas are young mountains, geologically active and fragile. The site chosen for the bridge presented a complex geological puzzle.

- Seismic Threat: The bridge is located in Seismic Zone-V, the highest-risk category in India. This means it had to be designed to withstand powerful earthquakes. Extensive site-specific seismic analysis was conducted. The structure is engineered to remain stable even during a quake of magnitude 8 on the Richter scale.

- Fragile Slopes: The steep slopes of the gorge were prone to landslides. Stabilizing these slopes was a massive undertaking in itself. Engineers used techniques like rock bolting, shotcreting, and building retaining walls to secure the foundations.

- Complex Foundations: The foundations for the massive arch had to be anchored deep into the rock. This required extensive excavation and detailed geological surveys to ensure absolute stability.

Battling the Elements: Extreme Weather and Wind

The weather in the Chenab gorge is unforgiving.

- High-Velocity Winds: The V-shaped gorge acts as a wind tunnel, creating extremely high wind speeds. To counter this, the bridge design underwent extensive wind tunnel testing at a specialized facility in Denmark. The truss design of the arch allows wind to pass through, reducing pressure on the structure.

- Temperature Extremes: The region experiences a wide range of temperatures, from scorching summer heat to freezing winters. The steel used had to be capable of handling this thermal expansion and contraction without compromising its structural integrity.

- Rain and Snow: Heavy monsoons and winter snowfall added to the construction difficulties. They often halted work and made access to the site perilous.

A Fortress in the Sky: Unmatched Security and Safety Features

Given its strategic location, the bridge was designed with security as a top priority.

- Blast-Proof Steel: In consultation with India’s Defence Research and Development Organisation (DRDO), the bridge was constructed using special blast-proof steel. It is designed to withstand major explosions and continue to be functional.

- Continuous Monitoring: The bridge is fitted with a vast network of sensors. These sensors monitor structural health, wind speed, temperature, and seismic activity in real-time. An alarm system will trigger, stopping train movement if any parameter exceeds the safe limit.

- Redundancy in Design: The structure has built-in redundancy. This means that even if one of its piers or supporting members is damaged, the bridge will not collapse immediately. This provides valuable time for evacuation and repairs.

The Logistical Nightmare: Access and Material Transport

Perhaps one of the greatest challenges was simply getting there. The bridge site was remote and inaccessible.

- Building Access Roads: Before any work on the bridge could begin, over 22 kilometers of new access roads had to be carved into the mountainside. This was a major civil engineering project in its own right.

- Transporting Heavy Components: Moving the massive steel segments, construction machinery, and raw materials to the site was a monumental task. Every piece of the 28,000-tonne steel superstructure had to be transported up treacherous mountain roads.

- Manpower in Isolation: Thousands of workers, engineers, and supervisors lived in dedicated camps near the site for years. Providing for them in such a remote location required a robust support system.

Engineering an Icon: The Step-by-Step Construction of the World’s Highest Railway Bridge

The construction of the world’s highest railway bridge was a symphony of precision engineering and heavy lifting. It was executed in a series of carefully planned phases, each a marvel in itself. The Konkan Railway Corporation Limited (KRCL) spearheaded this complex execution.

Step 1: Laying the Foundations

The journey began deep within the earth. Massive excavations were carried out on both the Kauri and Bakkal ends of the gorge. These excavations paved the way for the enormous concrete foundations that would support the steel arch. These foundations were anchored into the stable dolomite rock, ensuring the entire structure had an unshakeable base.

Step 2: Erecting the Approach Viaducts

Simultaneously, work began on the approach viaducts. These are the long, elevated sections of the bridge that lead to the main arch. Tall, slender concrete piers were constructed. A technique called slip-form construction was used for these piers, allowing for continuous and rapid vertical construction. Girders were then launched across these piers to form the deck.

Step 3: The Mighty Cable Crane System

A key innovation that made the construction possible was the installation of a massive cable crane system. This system, one of the largest in the world, stretched across the 915-meter-wide gorge.

- Two huge pylons, one on each bank, were erected to support the cables.

- The crane acted like a sky-lift, capable of carrying the heavy steel segments of the arch from the workshop to their exact position for installation.

- This eliminated the need to build a support structure from the riverbed up, a task that would have been impossible in the deep gorge.

Step 4: Building the Arch from Both Sides

This was the most visually dramatic phase of the project. The steel arch was constructed using the cantilever method.

- Segment by Segment: The arch was built from both sides of the gorge simultaneously.

- Lifting and Placing: The cable crane would lift a prefabricated steel segment, transport it over the gorge, and lower it into position.

- Securing the Segments: Workers, tethered securely hundreds of meters in the air, would then bolt the new segment to the previously installed one.

- Temporary Stays: To support the growing, unsupported arch halves, they were temporarily held in place by stay cables anchored to the rock behind them. This process was repeated, piece by piece, as the two halves of the arch slowly reached for each other over the Chenab River.

Step 5: The ‘Golden Joint’ – A Moment of Triumph

On April 5, 2021, the world watched as the final, central piece of the arch was lowered into place. This crucial element, known as the ‘Golden Joint,’ connected the two cantilevered halves. Its successful installation marked the structural completion of the arch. It was a moment of immense pride and a major milestone for Indian Railways engineering. The precision required was incredible, with tolerances of just a few millimeters.

Step 6: Laying the Deck

With the arch complete, it now served as the primary support for the final phase. Girders were launched over the arch, and the concrete deck was laid on top of them. Finally, the railway tracks were placed, completing the link and paving the way for the first train to cross the world’s highest railway bridge.

The Technology Behind the Triumph

The Chenab Bridge is not just about scale; it’s about advanced technology. Several cutting-edge technologies were employed to ensure its safety, longevity, and resilience.

- Advanced Material Science: The bridge uses a special grade of structural steel (E250 Grade C). This steel can withstand extreme temperatures and has high ductility, which is crucial for earthquake resistance.

- Sophisticated Design Software: Complex 3D modeling and analysis software, like Tekla and STAAD.Pro, were used. They simulated the effects of wind, earthquakes, and other loads on the structure, allowing engineers to perfect the design before a single piece of steel was cut.

- Phased Array Ultrasonic Testing: To ensure the quality of every weld, a non-destructive testing method called Phased Array Ultrasonic Testing was used. This advanced technique can detect even the tiniest flaws in the welds, ensuring the structural integrity of the thousands of joints.

- Structural Health Monitoring (SHM) System: As mentioned earlier, the bridge is a “smart” structure. The SHM system uses a network of fiber optic sensors, accelerometers, and GPS units. This system provides a continuous health report of the bridge, enabling proactive maintenance and ensuring safety.

- DRDO’s Blast-Proof Expertise: The collaboration with DRDO was vital. They provided the technical know-how to design the bridge to be blast-proof, a unique feature for a civil engineering structure of this scale.

More Than a Bridge: The Strategic and Economic Impact

The completion of the Chenab Bridge and the larger USBRL project is a game-changer for the Jammu and Kashmir region and for India as a whole.

- All-Weather Connectivity: For the first time, the Kashmir Valley will have a reliable, all-weather transportation link with the rest of the country. This will end its winter isolation and ensure a steady supply of essential goods.

- Economic Boom: The railway will significantly boost the region’s economy. It will make it easier and cheaper to transport agricultural products like apples and saffron to markets across India. Furthermore, it is expected to lead to a massive increase in tourism.

- Strategic Importance: The bridge provides a crucial alternate route for the movement of military personnel and equipment to the border regions. This greatly enhances the country’s strategic and defense capabilities.

- A Symbol of National Pride: The bridge stands as a powerful symbol of ‘Aatmanirbhar Bharat’ (Self-Reliant India). It showcases the ability of Indian engineers, planners, and workers to execute world-class mega-projects in the most challenging conditions.

Frequently Asked Questions (FAQ)

How high is the Chenab Bridge compared to the Eiffel Tower?

The Chenab Bridge is 359 meters (1,178 feet) high from the riverbed. This makes it approximately 35 meters (115 feet) taller than the Eiffel Tower in Paris, which stands at 324 meters.

Is the Chenab Bridge operational for trains?

As of early 2024, the bridge structure is complete, and track-laying work is finalized. Trial runs have been conducted successfully. The bridge is expected to be fully operational and open for regular train services as part of the complete USBRL project soon.

What material is the Chenab Bridge made of?

The main arch and the bridge deck are constructed from approximately 28,660 metric tonnes of special structural steel. The foundations and the piers of the approach viaducts are made of reinforced concrete.

Who designed and built the Chenab Bridge?

The bridge was designed by a consortium of consultants, including WSP (Finland) and Leonhardt, Andrä und Partner (Germany). The construction was executed by the Konkan Railway Corporation Limited (KRCL), a public sector undertaking of Indian Railways, with Afcons Infrastructure handling the main arch construction.

What was the approximate cost of the Chenab Bridge?

The Chenab Bridge alone cost approximately ₹14,000 crores (around 1.7 billion USD). This is part of the larger USBRL project, which has a total estimated cost of over ₹35,000 crores.

A Landmark for Generations: The Future of the Chenab Bridge

The Chenab Bridge is more than steel and concrete. It is a landmark that will be studied by engineers and admired by travelers for generations. Its 120-year design life ensures it will witness the continued growth and integration of the Kashmir Valley. It has already secured its place in the annals of global engineering, alongside marvels like the Golden Gate Bridge and the Millau Viaduct.

As trains begin their journey across this sky-high marvel, they will carry more than just passengers and goods. They will carry the hopes of a region, the pride of a nation, and the legacy of every single person who dared to dream and build the world’s highest railway bridge. It is a silent, strong sentinel in the Himalayas, a permanent tribute to the power of human will.